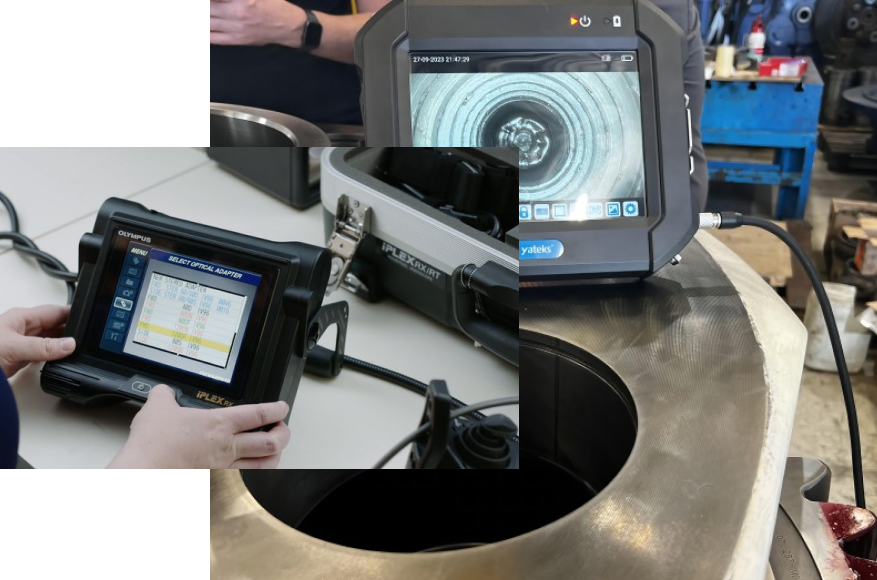

Videoscope & Borescope for Flawless Inspection

Videoscope and borescope technology revolutionize inspection by providing crystal-clear, real-time visuals of hard-to-reach areas without dismantling equipment. Whether detecting hidden defects, cracks, or corrosion in machinery, pipelines, or aviation components, these advanced tools ensure flawless precision and maximum efficiency. With high-resolution imaging and flexible probes, they make the invisible visible, enhancing safety, reducing downtime, and optimizing performance like never before!

- Access hard-to-reach areas without dismantling equipment.

- Capture crystal-clear visuals for precise defect detection.

- Perfect for aviation, automotive, oil & gas, and manufacturing.

- Detect cracks, corrosion, and defects with unmatched accuracy.

- Reduce downtime and maintenance costs with quick, accurate diagnostics.

Limitations

Videoscope and borescope technology offer unparalleled access to hidden areas, but they come with certain challenges. Limited probe reach may restrict deep or complex inspections, and poor lighting conditions can impact image clarity. Additionally, high-quality equipment comes at a premium, making it a costly investment for many industries.

Beyond equipment constraints, operator expertise is crucial—misinterpretation of visuals can lead to incorrect diagnostics. Despite their flexibility, some intricate structures remain inaccessible, and delicate probes require careful handling to avoid damage. While these limitations exist, strategic use of this technology ensures effective, high-precision inspections in critical applications.

The Videoscope & Borescope requires at least five steps:

Videoscope and borescope inspection is a non-destructive testing (NDT) technique used to examine hard-to-reach areas within machinery, pipelines, engines, and other critical components. These advanced tools use a flexible or rigid probe with a high-resolution camera to capture real-time visuals, allowing operators to detect cracks, corrosion, leaks, and blockages without disassembling equipment.

01

Preparation & Setup

Ensure the videoscope or borescope is clean, calibrated, and functional. Choose the right probe size and length, and check lighting, focus, and camera settings for clear imaging.

02

Probe Insertion

Gently insert the flexible probe, navigating tight spaces carefully to avoid damage. Handle with precision to ensure smooth movement for a thorough scan.

03

Real-Time Observation

Live video or high-resolution images display defects instantly, helping identify cracks, corrosion, leaks, or blockages for accurate assessment.

04

Data Capture & Analysis

Key images/videos are recorded for analysis. Advanced software enhances visuals, measures defects, and tracks changes over time.

05

Reporting & Decision Making

A detailed inspection report is created, including findings and recommendations. Necessary repairs or maintenance are planned to ensure safety and efficiency.

Why Choose Us for Videoscope & Borescope?

- Capture detailed visuals for precise detection of defects.

- Inspect components without the need for disassembly.

- Ideal for industries like aviation, automotive, and oil & gas.

- Live video feeds for immediate detection of issues.

- Navigate tight spaces and complex structures with ease.

- Reduce downtime and maintenance costs through quick inspections.

- Receive clear, comprehensive reports with findings and recommendations.

- Skilled technicians ensure accurate interpretation and decision-making.

1

Non-Destructive

Inspect critical components without the need for disassembly, preserving the integrity of the equipment.

2

High-Precision Detection

Detect hidden issues like cracks, corrosion, and blockages with high-resolution, real-time imaging.

3

Cost and Time Efficient

Minimize downtime and reduce maintenance costs by identifying problems early and avoiding unnecessary repairs.

Videoscope & Borescope are inspection tools used to view hard-to-reach or internal areas of machinery and structures. A videoscope uses a flexible probe with a high-resolution camera to provide real-time video of the area being inspected, while a borescope typically has a rigid probe for more precise inspections. Both tools are ideal for non-destructive testing (NDT), detecting issues like cracks, corrosion, or blockages without disassembling equipment.

Aviation, automotive, oil & gas, manufacturing, and industrial maintenance.

Cracks, corrosion, blockages, leaks, wear & tear, and improper assembly.

Yes, it allows inspection without dismantling equipment.

High-resolution imaging, real-time analysis, cost savings, and improved safety.

It depends on the probe length, which can range from a few inches to several meters.